# Drone Tank Inspections Revolutionize Oil Storage Tank Maintenance

PERTAMINA, Indonesia's national energy company, partnered with Halo Robotics to revamp one of its massive oil storage tanks at the Balongan refinery. The Elios 2 drone played a pivotal role in this drone tank inspection, delivering results that surpassed expectations.

## Key Benefits At A Glance

### Safety

By employing the Elios 2 for visual data collection within the oil storage tank, the need for manual entry via rope access and scaffolding was eliminated, significantly enhancing safety for the inspection team.

### Return on Investment

Costly inconsistencies between asset owners and EPC contractors were minimized using the Elios 2. Savings were achieved through reduced downtime and no longer needing to construct expensive scaffolding.

### Efficiency

The Elios 2 dramatically improved the efficiency of the oil storage tank inspection. New processes were developed, enabling systematic, repeatable inspections of aging assets for long-term analysis.

### Data Coverage

An Elios drone provides access to previously unreachable areas, collecting critical data swiftly. Teams can gather more information than ever before without the risks associated with human entry into confined spaces.

## Introduction

PERTAMINA is Indonesia’s leading energy provider. To enhance its maintenance practices, the company engaged Halo Robotics, a drone technology firm based in Jakarta, to assist with a significant maintenance initiative at its Balongan refinery, which has a processing capacity of 125 mbsd (Thousand Barrels per Stream Day).

The specific asset targeted for refurbishment was a large bulk crude oil storage tank.

This tank shares characteristics identical to those of API 650 tanks, widely used globally for storing bulk crude oil and gasoline, making the methods and outcomes applicable to any refinery utilizing such tanks.

*Photo of the oil storage tank at the Balongan refinery.*

## Innovating Oil Storage Tank Inspections

PERTAMINA needed to conduct a thorough inspection of a massive crude oil storage tank at its Balongan refinery.

With a capacity of up to 37,000 m3, this tank was not only immense but also quite old, having been constructed in 1972.

PERTAMINA's objectives for this project included:

- Updating the tank’s original 1972 blueprints with current as-built schematics.

- Conducting a systematic internal inspection to determine EPC (Engineering, Procurement, and Construction) needs.

- Minimizing risk for inspection personnel by reducing the need for rope access and manned entry into tanks across the refinery.

- Enhancing the overall efficiency of EPC maintenance processes, including planning and execution.

A critical aspect was ensuring that the data gathered would be compatible with all stages of maintenance planning and execution for the tank.

To achieve these goals, PERTAMINA divided the work into two distinct outputs:

- Creating a Digital Twin to generate updated as-built schematics and structural data via a 3D scan of the tank.

- Performing a Confined Space Inspection to execute a comprehensive Close Visual Inspection (CVI) of the tank’s interior.

The ultimate aim was to develop replicable processes that could be applied across PERTAMINA’s nationwide operations.

*(Note: This case study focuses solely on the Confined Space Inspection. For more details on the Digital Twin creation, refer to Halo Robotics' full white paper.)*

*Inspectors working inside the oil storage tank.*

## Employing The Elios For Drone Tank Inspections

PERTAMINA entrusted drone technology experts at Halo Robotics to integrate advanced solutions for both outputs: creating a Digital Twin and conducting a Confined Visual Inspection.

For the confined space inspection, Halo Robotics opted for Flyability’s Elios drone, appreciating its features such as:

- A collision-tolerant cage, ideal for indoor inspections, allowing safe contact with assets.

- High-quality image capture with a 4K RGB camera and thermal IR camera.

- Professional lighting capabilities with 10,000 Lumen LED lights for precise defect identification.

- Advanced stabilization and distance-lock systems for stable flight in GPS-denied environments.

- User-friendly software for efficient data review and report generation.

*The Elios 2 flying inside the oil storage tank during the drone tank inspection. The Elios 3 now offers LiDAR and close visual data capture options.*

## Gathering Visual Data During The Drone Tank Inspection

The Elios 2 far exceeded PERTAMINA's expectations for the confined space inspection.

Compared to conventional methods requiring physical entry with rope access and scaffolding, the Elios drone offered substantial improvements, including saving time and costs, boosting safety, and streamlining inspection efficiency.

“The results we’ve obtained with this drone technology have truly exceeded our initial expectations. Such drone operations will greatly support preventive maintenance efforts, helping us locate specific defects, apply the right maintenance strategies, and achieve significant gains in speed and accuracy.â€

-Almuayat Librata, Oil and Gas Transportation Manager at Pertamina EP

## Drone Tank Inspection Mission Details

Halo Robotics designed flight plans targeting specific parts and structures within the tank, including the tank shell, welds, rafters, girders, joints, and roof.

Over five days, 20-22 inspection flights were executed daily with the Elios 2, resulting in 760 GB of inspection video footage (both RGB 4K video at 9 fps in .mp4 format and thermal video in .thm).

Post-collection, the visual and thermal data was processed offsite into a formal inspection report using Flyability’s Inspector software.

Halo Robotics highlighted that Inspector enabled efficient review of large volumes of raw 4K RGB and thermal video, selection of Points of Interest (POIs), and annotations for detailed inspection analysis. Final reports were also generated with thermal video overlaid onto RGB color video for comparison.

The entire process, from review to report completion, took 14 days, including a comprehensive inspection annotation by an API-certified inspector.

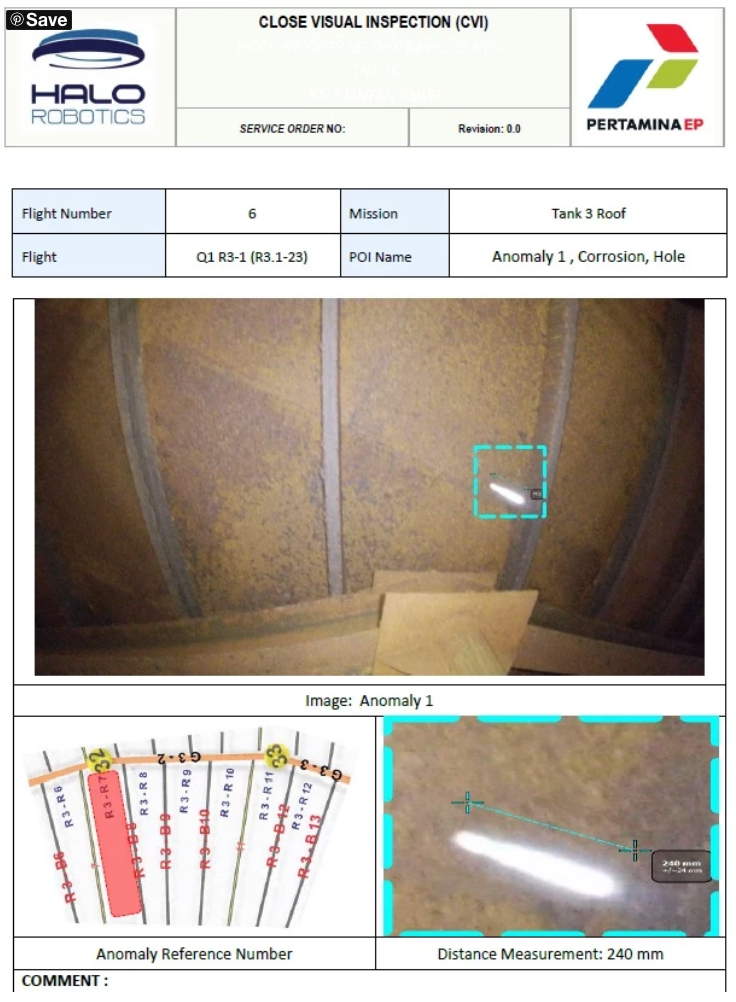

## Point Of Interest (POI) Reporting Examples

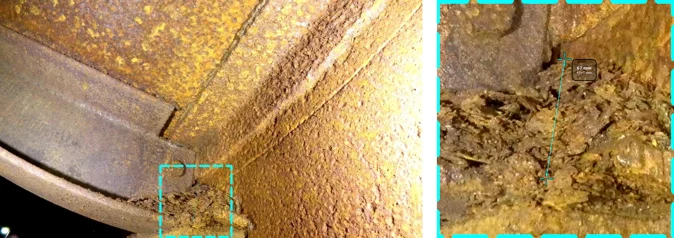

**Corrosion Identified – Tank Joint Left Side**

*Inspector Comments:*

- Counted 2 bolts.

- Observed shrinking steel plating and supports.

- Noted significant corrosion extending 0 mm - 67 mm from the joint.

- Measured distance: 67mm ± 5mm.

**Flaking and Oil Material Build-Up Observed – Tank Joint Right Side**

*Inspector Comments:*

- Counted 2 bolts.

- Noted significant flaking or oil material deposits, building up to 67 mm in height.

- Detected homogeneous deep corrosion.

- Observed deformation and exposure of raw metal to oxidation and galvanic reactions.

- Measured distance: 67mm ± 5mm.

*Sample report generated by Flyability’s Inspector software.*

## Looking Toward Future Drone Tank Inspections

PERTAMINA personnel view Halo Robotics’ use of the Elios drone as a major success.

The confined space inspection proved that even the largest oil storage tanks can be systematically examined by drone, meeting API-certified standards while eliminating the need for risky, costly manned entry.

“We firmly believe that adopting this kind of drone technology will transform tank inspections by reducing risks and costs while improving safety and efficiency.â€

-Erikson Nainggolan, Operation Planning Assistant Manager at Pertamina EP

Having successfully completed this project, PERTAMINA is now collaborating with Halo Robotics to explore further applications of drone technology in other maintenance projects across its Indonesian refineries.

---

*(Word count: 975)*

DRI Reformer Tube,Cast Refomer Tube,Reformer Tube Material,Reformer Catalyst Tube

Tuopu Industry(Jiangsu) Co., Ltd. , https://www.tuopu-industry.com