# Everything You Need to Know About Bridge Inspections

Bridge inspections are an essential component of maintaining critical infrastructure and ensuring public safety. They allow engineers to spot minor defects before they escalate into major issues, preventing catastrophic incidents like bridge collapses. Given their importance, bridge inspections are regulated by laws in most countries.

In this comprehensive guide, we’ll explore what’s involved in bridge inspections, the different types and techniques used, the challenges faced, regulatory considerations, the role of bridge inspectors, and how drones are revolutionizing the inspection process.

---

## What Is a Bridge Inspection?

Many of us take bridges for granted, yet millions of bridges worldwide are constantly in use. In the U.S. alone, there are over 700,000 bridges, all requiring regular inspections and maintenance to ensure safety. Practices and regulations vary globally, but most countries require bridges to be inspected at least once every two years.

Inspectors conducting bridge inspections typically search for flaws, defects, or potential problem areas. The aim is to identify issues early before they become severe. Traditional bridge inspections involve the use of bucket trucks (or "snooper trucks"), designed to operate in rugged environments. These trucks enable inspectors to examine the underside of bridges safely.

*Image: Bridge inspections using traditional snooper trucks.*

A snooper truck can climb steep inclines, operate in deep water, and lower a bucket for inspectors to access hard-to-reach areas beneath bridges.

---

## Types, Techniques, and Challenges of Bridge Inspections

### Types of Bridge Inspections

Bridge inspections come in various forms, each tailored to specific needs:

- **Periodic Inspection**: Often referred to as routine inspections, these follow a legally mandated schedule. Inspectors compare the current condition of the bridge to the last inspection, ensuring compliance with safety standards.

- **Fracture-Critical Member Inspection**: Focuses on components critical to the bridge’s stability. These inspections aim to detect weaknesses that could lead to structural failure.

- **Underwater Inspection**: Covers submerged elements of a bridge, requiring specialized diving equipment and trained personnel.

- **Damage Inspection**: Urgent inspections are conducted when damage is suspected or already identified.

### Techniques Used

While visual inspections remain the most common, inspectors employ other methods to gain deeper insights:

- **Visual Inspections**: Inspectors examine bridges visually, either directly or remotely using tools like drones. Remote visual inspections offer a safer alternative to direct access.

- **Acoustic Inspections**: By listening to changes in sound pitch, inspectors can detect material splits or separations in the bridge’s structure.

- **Thermal Inspections**: Thermal imaging identifies temperature anomalies that could signal degradation or delamination in concrete.

- **Ground-Penetrating Radar (GPR)**: Electromagnetic waves help visualize the internal structure of bridges to locate hidden defects.

Introducing advanced technologies, such as drones, can significantly enhance bridge inspections. Drones provide detailed imagery and access to hard-to-reach areas without risking human safety.

*Image: Drone inspections for safer and more efficient bridge assessments.*

### Unique Challenges

Bridge inspections pose distinct challenges:

- **Traffic Management**: Deploying snooper trucks requires extensive traffic control, making logistics complex.

- **Staffing Requirements**: At a minimum, two people—one operating the truck and another inspecting—are needed. Additional personnel may be required for traffic management.

- **Access Constraints**: Even with a snooper truck, accessing all parts of a bridge can be difficult due to tight spaces and structural barriers.

- **Cost Implications**: Snooper trucks are costly, with purchase prices exceeding $600,000 and daily rentals reaching $2,500. Staff costs further add to the expense.

Drones can help overcome some of these challenges by reducing reliance on heavy machinery and minimizing risks to personnel.

---

## Regulatory Considerations

Each country establishes its own set of rules for bridge inspections. These guidelines usually specify:

- Which types of bridges require inspection,

- How frequently inspections must occur,

- And the qualifications necessary for inspectors to perform legally recognized inspections.

In the U.S., federal and state regulations govern bridge inspections. The National Bridge Inventory Standards (NBIS) outlines the following inspection intervals:

- Routine inspections: Every 24 months

- Fracture-critical member inspections: Every 24 months

- Underwater inspections: Every 60 months

States often impose stricter requirements than the NBIS, including expanded definitions of bridges subject to inspection, increased frequency, and variations in inspection types.

---

## The Role of Bridge Inspectors

Bridge inspectors play a vital role in ensuring structural integrity. During inspections, they look for signs of deterioration such as cracks in concrete, rust, corrosion, or loose bolts. Electrical infrastructure is equally important, as outdated wiring or poorly executed repairs can compromise safety.

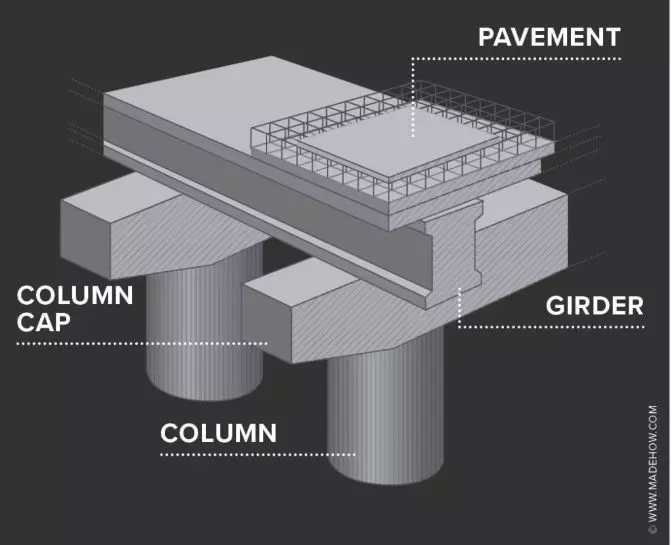

Inspectors must also check bearings (if applicable), assess structural stability, and evaluate the condition of the deck and superstructure. Below is an infographic highlighting key areas of focus during bridge inspections:

*Image: Key areas inspected during bridge evaluations.*

Bridge inspectors typically need certification, such as those offered by the Federal Highway Administration (FHA) in the U.S. Certification ensures inspectors meet rigorous standards and understand the latest best practices.

---

## Conclusion

Bridge inspections are indispensable for maintaining safe infrastructure. While traditional methods like snooper trucks remain prevalent, innovations like drones are transforming the industry. These advancements reduce risks to personnel, improve efficiency, and provide valuable data to engineers.

By understanding the types of inspections, techniques, challenges, and regulations involved, stakeholders can better appreciate the importance of this critical task. Whether you're a government official, engineer, or concerned citizen, staying informed about bridge inspections is key to ensuring our infrastructure remains reliable and secure.

For further reading, visit the National Highway Institute’s website or consult the FHA for more details on bridge inspection certification.

*Image: Advanced drone technology enhancing bridge inspections.*

---

Let us know if you have questions about bridge inspections or need assistance with related projects!

19X7 Non-Rotating Steel Rope

19X7 Stainless Steel Wire Rope

construction : 19x7

Strandard: EN12385-4 , DIN3055

Diameter: from 3mm to 20mm. 19x7 3.0mm,19x7 4mm,19x7 5mm, 19x7 6mm,19x7 8mm,19x7 10mm are normal

diameter.

Tensile strength : 1570N/mm2.

packing term:wooden reel,plastic reel or coils, Length per

package : 25meters,50meters,100meters,150meters,200meters,250meters,500meters,1000meters,2000meters

and so on.we can pack according to customer's request.

Stainless Steel Wire rope is made of AISI304 or AISI316

material , They have good features for resisting corrosion , heat and low temperature,

applied to various fields such as Petrochemical Industries, aircraft ,

automobile, fishing ,precise instrument, building industry and so on. We can

supply all grades Stainless steel material according to your requirements.After

Electrolytic Polishing , The ropes become better shining and clean , Resisting

corrosion becomes stronger.

19X7 Non-Rotating Steel Rope,19X7 Steel Wire Rope,19X7 Stainless Steel Wire Rope,19X7 Non-Rotating Steel Wire Rope

JIANGSU RUIJIN SLING CO.,LTD. , https://www.cnsteelcable.com